British American Absorption Plant

B-A Plant looking NW

Introduction

Fortunately, we can enjoy tours of the Turner Valley Gas Plant because the facility has been conserved. Several other similar facilities once existed in the Turner Valley to Longview area. They are but memories now since all signs of surface installations were removed.

Over time photos and maps have been donated to the Turner Valley Oilfield Society. On a recent field trip to this historical area with men who worked at these “other” facilities a few comments and stories were recorded.

British American (B-A) Absorption Plant

NOTE: Location was toured with A.E. (Sid) Robinson and David Evans May 22, 2019

Location:

➢ Facilities were located approximately 1 mile east of Longview and ¼ mile north of Township Rd. 183; legal location = 4-22-18-2W5M (see annotated topographic map)

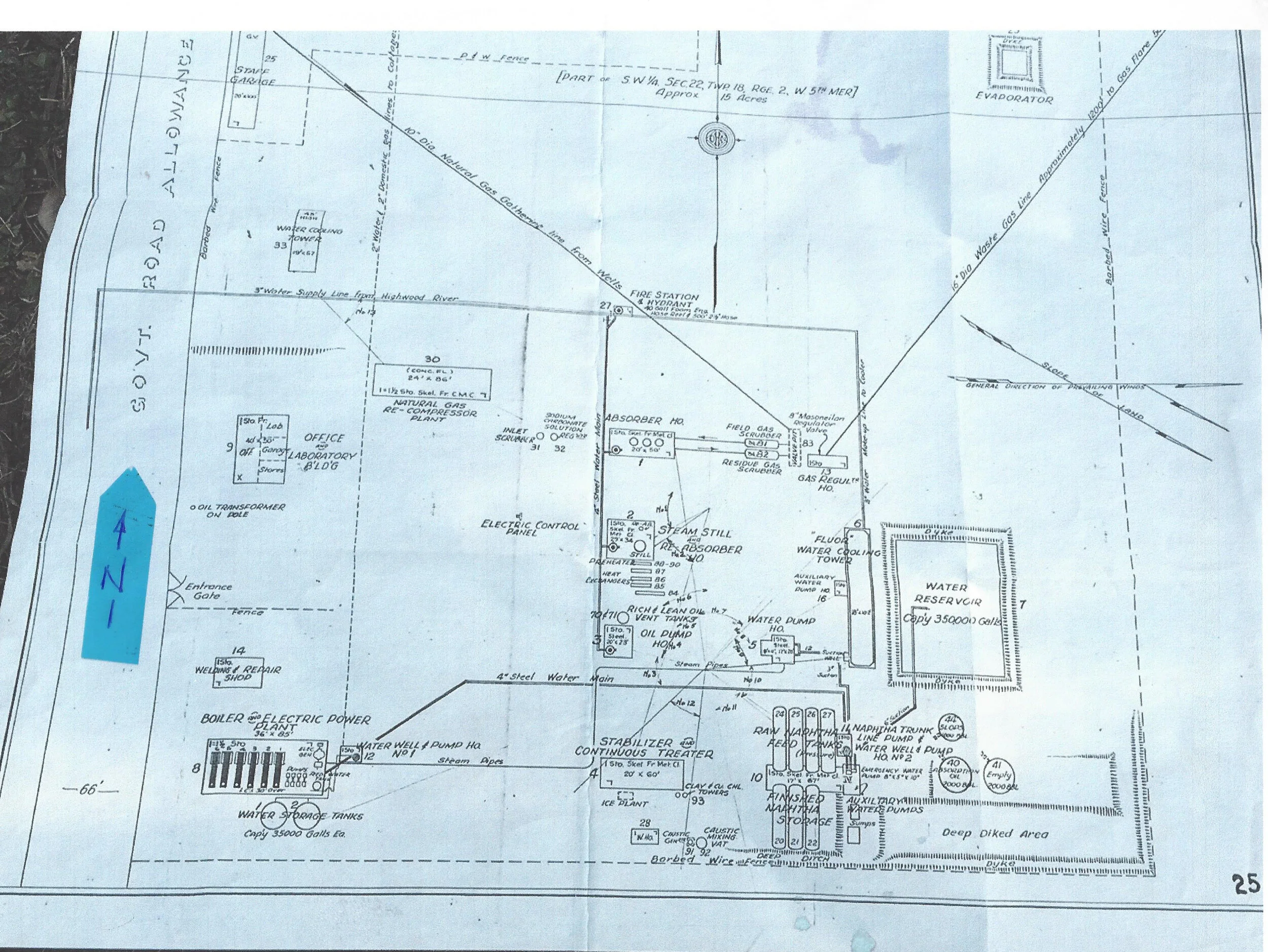

Facilities:

The British American (B-A) gas processing facilities were similar to the Anglo-American facilities near Hartell (3.5 miles to the north). Lean oil absorption was used to recover light hydrocarbon (HC) liquids (aka natural gasolene or raw condensate or naptha) from the nearby gas wells.

This plant was built in 1936 and was able to remove HC liquids from an inlet gas stream of 62 million cubic feet per day (62 mmcfd).

It was later expanded to process 80 mmcfd (see B-A expansion article)

➢ As there was no market for the surplus natural gas it was initially flared to the north east of the plant site via a 16-inch diameter pipe. In 1946 gas compression was installed and the processed gas was then pipelined to the Turner Valley Gas Plant for sale to the City of Calgary (see July 1946 B-A Commentator article by C.W. Coote).

➢ David Evans’ father was an engineer for B-A and supervised installation of these facilities (see aerial photo).

➢ Six locomotive steam boilers provided heat and power to the processing facilities.

➢ A cooling water tower at this site was used to provide process cooling.

➢ Water for the boilers and the cooling tower was pumped from the Highwood River via pipeline (see plant plot plan drawing).

➢ The recovered HC liquids were pumped north to storage tanks on top of the "Longview" hill then sent via pipeline to the Turner Valley Gas Plant and from there pipelined to the Imperial Oil Refinery in Calgary.

➢ The unrefined, “natural gasolene” recovered at the B-A plant was of such quality that it could be used directly in (older) vehicles. David Evans recalled his 1949 Mercury half ton pickup ran very well on this product (also called naptha) though the motor exhaust was a bit smelly.

➢ The B-A plant was shut down in 1959 and dismantled shortly thereafter.

Residences, etc.:

➢ As was customary at the time, about 6 houses (no basements) were provided for the senior B-A operations personnel immediately north of the plant site as shown on the topographic map.

➢ Although quite small, these houses featured electricity, running water and flush toilets (thanks to services from the nearby B-A plant).

➢ One can imagine the noise from the flare burning up to 80 mmcfd 24/7/365 only a short distance east of these homes! No need for streetlights.

➢ Interestingly, about 4 of these houses remain at the original site (see photo with D. Evans).

➢ Other personnel lived along the adjacent north-south Gap Road or in Longview.

Author – A. R. Lambden, P.Eng.

B-A Plant annotated topographic map

B-A Plant Plot Plan

B-A Plant looking SE

B-A Plant company house 2019